Production

Production Destination

Given the efforts carried out by Rosario Bio Energy SA, in terms of authorizations, the quality of the product obtained, certified and the commercial efforts carried out, 100% of the biodiesel production is destined to supply the Argentine Domestic market, being its main clients Repsol-YPF, Petrobras, Esso, Shell. The crude glycerin and fatty acids are destined for different national industries that are dedicated to processing and transforming these products into others with greater added value.

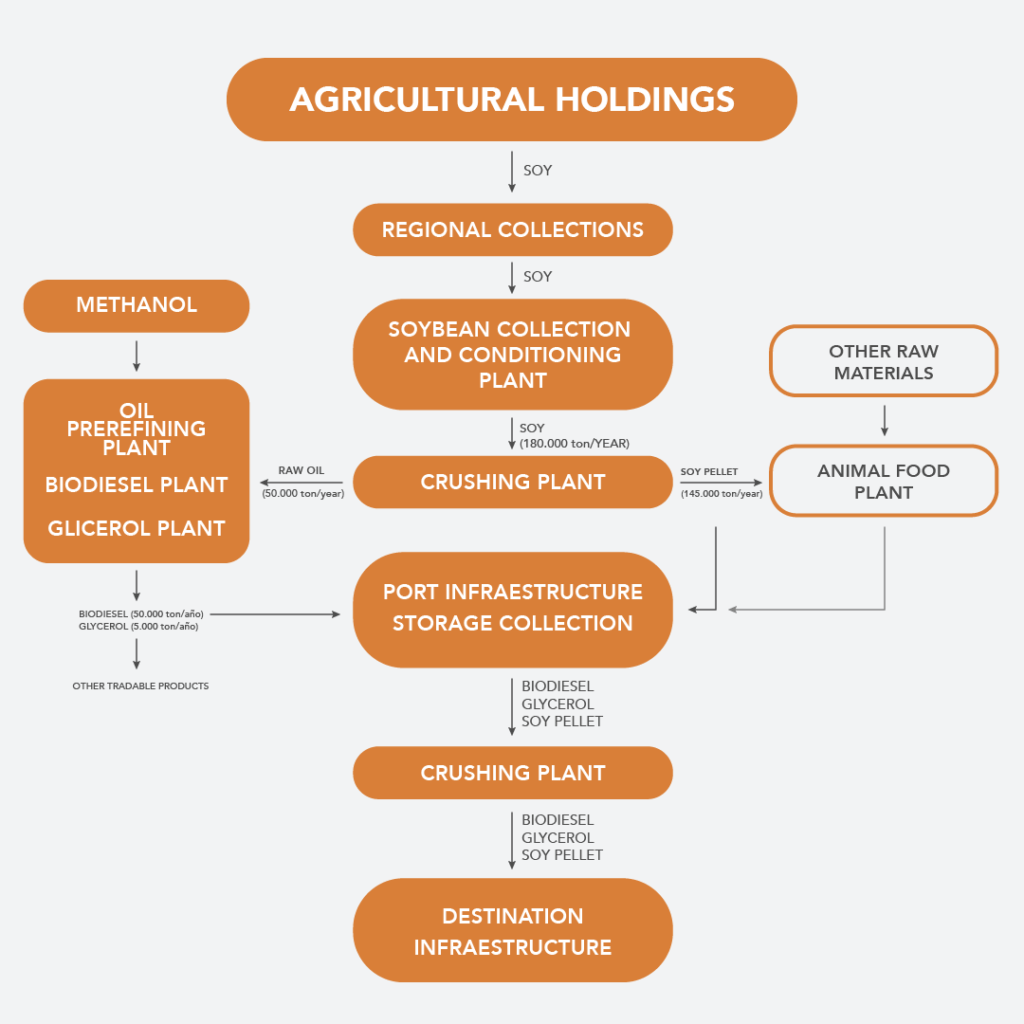

Stages of the process

Pre-refined Oil Plant (INITIAL STAGE): It carries out the treatment of crude soybean oil to condition it for the production of Biodiesel; Its production capacity will be 200 Tons/day.

Glycerol Biodiesel Plant (INITIAL STAGE): Produces Biodiesel (SME) and treats the glycerin phase for the production of Raw Glycerin. Initial capacity: 150 Ton/day.

It is composed of:

- Reaction stage

- Decantation stage

- Methanol recovery stage

- Washing and purifying stage

- Drying and cooling stage

- Face separation stage

- Fat breakdown stage

Complementary Infrastructure: Consistent with the previous Plants and their capacities, storage infrastructures for Biodiesel, Glycerol, oil and other inputs will be implemented in the capacities corresponding to the production level and to ensure a minimum stock of 7 days of production. This period of time allows us adequate supply and dispatch logistics, due to the proximity to the input and oil supply plants.

Production Process

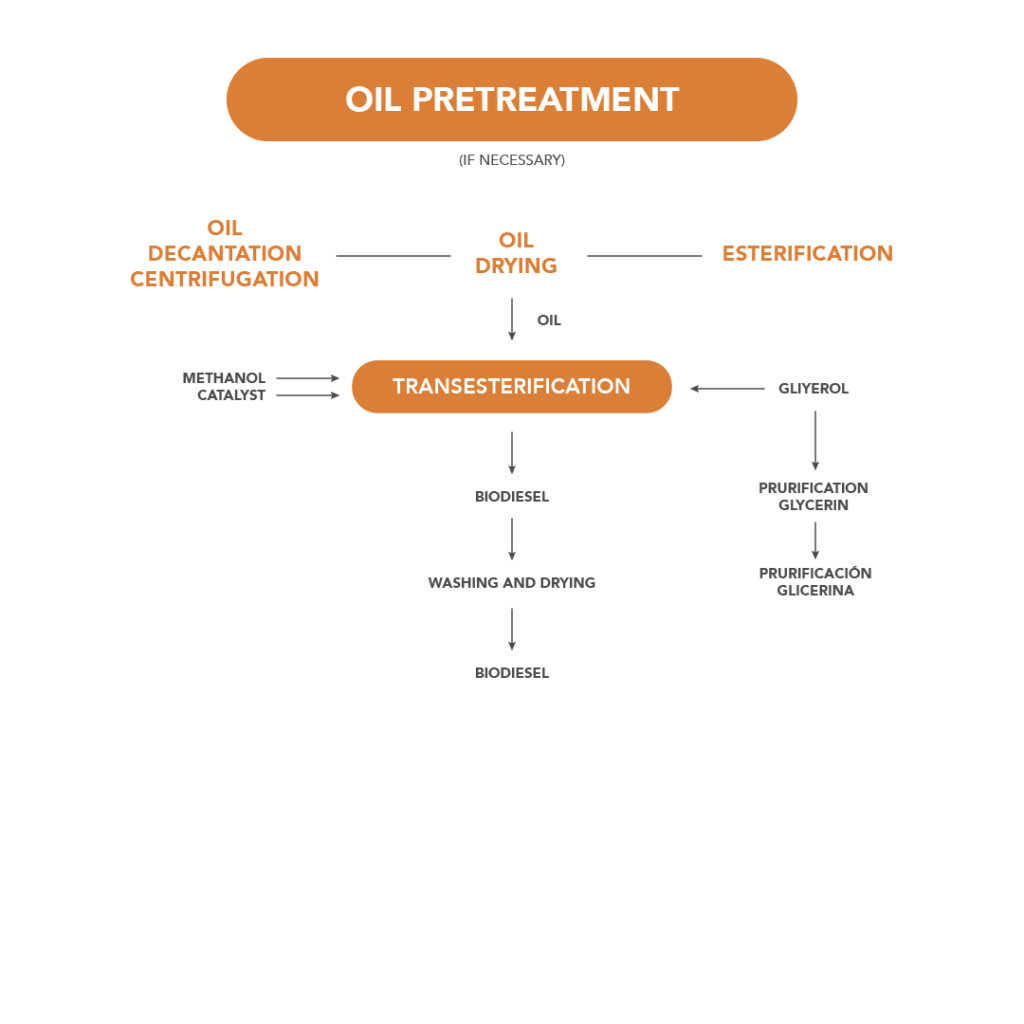

The obtaining process is summarized as follows:

TRIGLYCERIDE + METHANOL METHYL ESTER + DIGLYCERIDE DIGLYCERIDE + METHANOL METHYL ESTER + MONOGLYCERIDE MONOGLYCERIDE + METHANOL METHYL ESTER + GLYCEROL

In addition to the main reaction there is another series of processes that are also important:

- Pre-treatment of the oil, if necessary, to eliminate suspended solids by decantation and centrifugation.

- Drying the oil: it is also necessary to eliminate any moisture that the oil may carry to avoid later problems in the quality of the biodiesel.

- Washing and drying the biodiesel: In order to exclude excess methanol and catalyst remains, it is necessary to wash the biodiesel. To eliminate the washing water, it is necessary to dry it.

- Treatment of crude glycerin: The glycerol obtained is a crude glycerin with the presence of unreacted compounds, remains of catalyst, methanol and biodiesel. For this reason, it is necessary to carry out this operation not only to valorize the glycerin, but also to optimize the use of methanol.

In technical terms, the process requires the use of inputs to begin, among which the following stand out:

Available vegetable oils: soybean, sunflower, rapeseed, avu.

Soybean oil: lower market value than sunflower oil.

Rapeseed oil: higher production per planting area

AVU: (Used vegetable oil), rising market in quantity and quality.

Animal fats: limited supply but not negligible.

Alcohols: Methanol (from petroleum)

Since the biodiesel produced will comply with the IRAM 6515, EN 14214 and Law 26093 DEC 828/10 standards, the conditions for entering the oil into the neutralization process must be guaranteed.